Your gearbox

operation and maintenance expertAs one of the largest annual events in the global wind power industry, the China Wind Power (CWP) 2021 opened up in Beijing to focus on the future of China’s energy revolution.

At the CWP 2020, representatives from more than 400 wind energy companies around the world jointly signed and issued the “Beijing Declaration on Wind Energy: Developing 3,000 GW of Wind Power, Leading Green Growth, and Achieving China’s 2060 Carbon Neutrality Target”. In 2020, China added 71.67 million kilowatts of grid-connected installed capacity of wind power, hitting a record high. In 2021, the first year of the “14th Five-Year Plan” period, China’s newly installed grid-connected wind power capacity grew to 14.63 million kilowatts from January to August, an increase of 4.59 million kilowatts year-on-year. The industry expects to see an annual grid-connected installed capacity of wind power totaling 40-50 million kilowatts for 2021. As technology advances, more updated large-megawatt models with increasing intelligence become available, and the cost of wind power per kilowatt-hour has steadily decreased, making wind power a competitive option for China to achieve its carbon peak and neutrality targets.

Heeding the call of the times and a changing market, the HQ has always been committed to the operation and maintenance for wind turbines and striving for excellence in technology and service to meet market needs with higher and stricter technical standards. The HQ presented its latest wind gearbox repair technology at this event and attracted much attention.

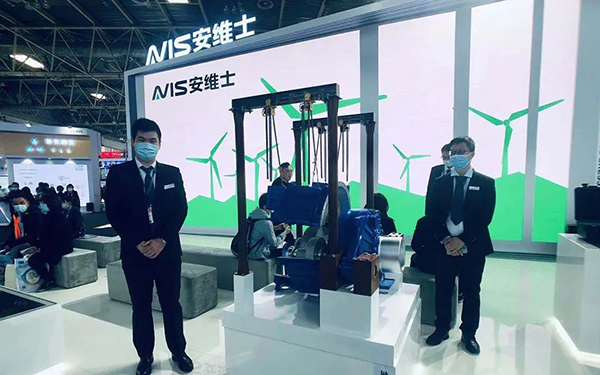

01 Live show of up-tower services

In case of a gearbox failure, the HQ technicians analyze the cause and, if necessary, provide up-tower services to reduce the repair time and customer loss. At the HQ’s stand, technicians performed a simulated gearbox repair up-tower, demonstrating every step of parts replacement. The HQ took this opportunity to showcase its strengths and reliability visually and clearly to the customers.

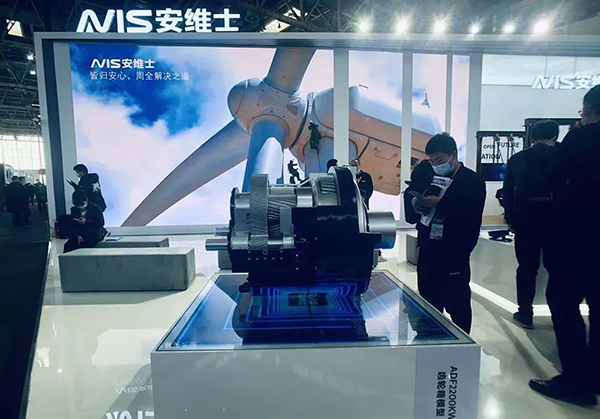

02 Alternative gearbox models

The HQ displayed the models created to illustrate its replaceable wind gearboxes. With detailed explanations of the models by the HQ technicians, visitors were informed of the inside of the gearbox and how it works.

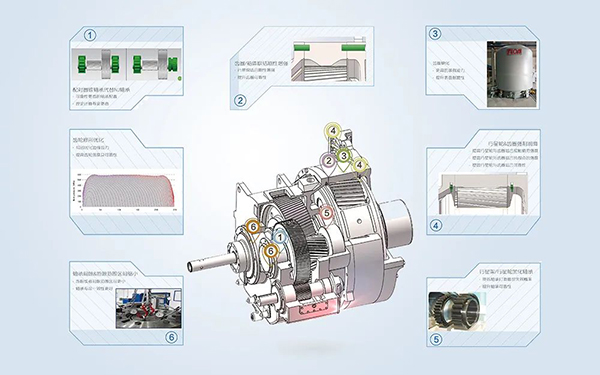

03 Failure monitoring platform

The A-PHM9000 failure monitoring platform developed by the HQ includes vibration monitoring and diagnosis, oil testing, physical parameters detection, customizable noise detection, and other modules. Leveraging the HQ’s recent R&D data and wind gearbox lifetime data collected onsite, the platform offers big data-driven services such as failure prediction, intelligent diagnosis, and health management for wind turbines.

04 Gearbox remanufacturing technology

When repairing a broken gearbox, the HQ technicians not only repair or replace the broken parts, but also conduct a root cause analysis to identify all the causes behind to minimize the likelihood of similar adverse events and optimize the points of failure to make the repaired gearbox more stable. Based on its experience in gearbox design, manufacturing and repair, the HQ provides various tailored maintenance plans to fix the common failure modes of specific gearbox models.

As the wind power industry expands, operation and maintenance technology and service modes are set to change, and the industry upgrading is inevitable. The HQ will continue to support the stable operation of turbine drive chains and do its best to promote the high-quality development of the industry.